In aerospace systems, precision timing is a must have and any deviation is a matter of large consequences. From satellite communications, to navigation systems and onboard avionics, every sub-system depends on very stable and accurate timing signals. In this regard, Custom Crystal Oscillators are critically important, providing performance that addresses the extreme needs of aerospace settings.

Environmental Challenges Demand Custom Solutions

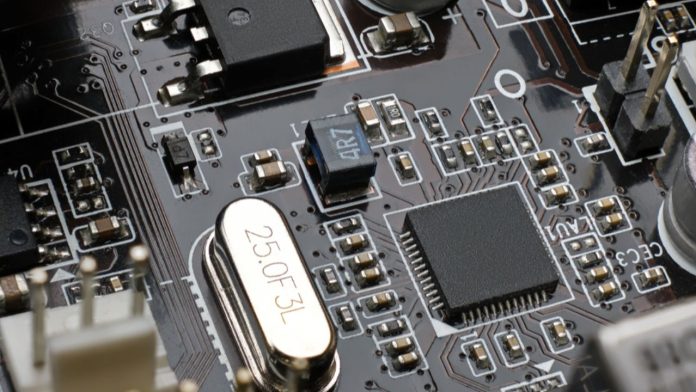

Aerospace environments are marked by great temperature variation, high vibration, and radiation in space. Such factors may significantly influence the work of standard oscillators. Custom crystal oscillators are built to withstand such hostile conditions. The design consideration might involve the use of temperature-compensated (TCXO) or oven-controlled crystal oscillators (OCXO). It can offer frequency stability over a wide range of temperatures. Shock and vibration resistance is also included in the mechanical design of the oscillator so that it can operate efficiently during launch, in flight, and landing.

Precision and Stability in the World of Change

Custom oscillators are calibrated to offer narrow frequency tolerances as well as minimum phase noise, both of which are important for aerospace communication and navigation systems. Since these systems tend to operate in a high-interference environment or at large distances, the stability of the oscillator provides for a clear transmission and reception of a signal. Long-term frequency stability is another important factor, especially for satellites and space probes that are far from the Earth, and maintenance and recalibration are impossible. Custom solutions are based on aging behavior and incorporate design attributes to minimize frequency drift with time.

Meeting Regulatory and Mission-Specific Requirements

The aerospace industry is regulated by strict standards and certifications. Specific custom crystal oscillators can be produced to fit these requirements, including compliance with radiation-hardened components for space missions. Furthermore, each aerospace mission could have its own technical requirements, e.g., size limitations, output formats, or power efficiency requirements. Custom oscillator design provides for specific solutions to these mission-specific requirements, without sacrificing performance or reliability.

Timing as a Critical Aerospace Systems Factor

Time is critical in aerospace applications in terms of safety and functionality. Synchronization is used in such operations as GPS receivers, radar, telemetry units, and flight control modules for them to function properly. Time lags or imprecision in time can compromise the quality of data, navigation, and real-time communication. Unlike the ordinary off-the-shelf components, custom crystal oscillators are designed to meet the strict timing tolerances of these mission-critical systems so that once they are installed, there will be smooth coordination and operation.

Innovation and Miniaturization

As aerospace systems are changing to accommodate smaller, lighter, and more power-efficient systems, custom crystal oscillators are also developing. Modern custom designs now incorporate improved functionality in smaller form factors, without sacrificing frequency stability or strength. These miniaturized oscillators make the system architecture more flexible and help with weight and energy savings, which are essential for long-duration missions. Furthermore, the progress made in the field of material science and microfabrication techniques keeps pushing the limits of aerospace timing technology, so even the smallest systems are able to stay on mission-critical synchronization and performance.

Conclusion

For aerospace applications where time is of the essence, and failure is not an option, custom crystal oscillators provide reliability, precision, and robustness against environmental conditions that standard components cannot. The ability to be designed for extreme conditions and mission-specific requirements makes them an important part of the modern aerospace systems’ design. With the aerospace industry ever striving to break the limits of innovation, the significance of high-performance custom timing solutions will only increase.