The Future of Engraving Technology in Flexographic Printing

Flexographic printing has been used in the packaging and labeling industry. It is one of the most efficient processes of printing on different materials. This printing process uses flexible relief plates. It is widely known for its efficiency in producing quality prints within the shortest time. That is why it is suitable for mass production. The ever-increasing need for higher quality prints, reduction of cost, and environmental concerns have been the force behind the advancement of engraving techniques in the field of flexographic printing. Let’s go now and explore the future of engraving technology.

New Development in Laser Engraving

That new technique in the field of flexographic printing is laser engraving technology. This technology makes use of laser beams for engraving images or patterns on the printing plates. The advantages of laser engraving include better accuracy and repeatability. The possibility of engraving intricate patterns with small elements.

Digital Engraving

Digital engraving along with automation has taken flexographic printing to another level and has given it a new direction. Digital engraving is a process by which digital files are easily converted into engraved plates. It helps save a lot of time in the production of plates. This also helps in improving the accuracy of the prints and at the same time helps in fast prototyping and making changes if required to meet the customer requirements on time.

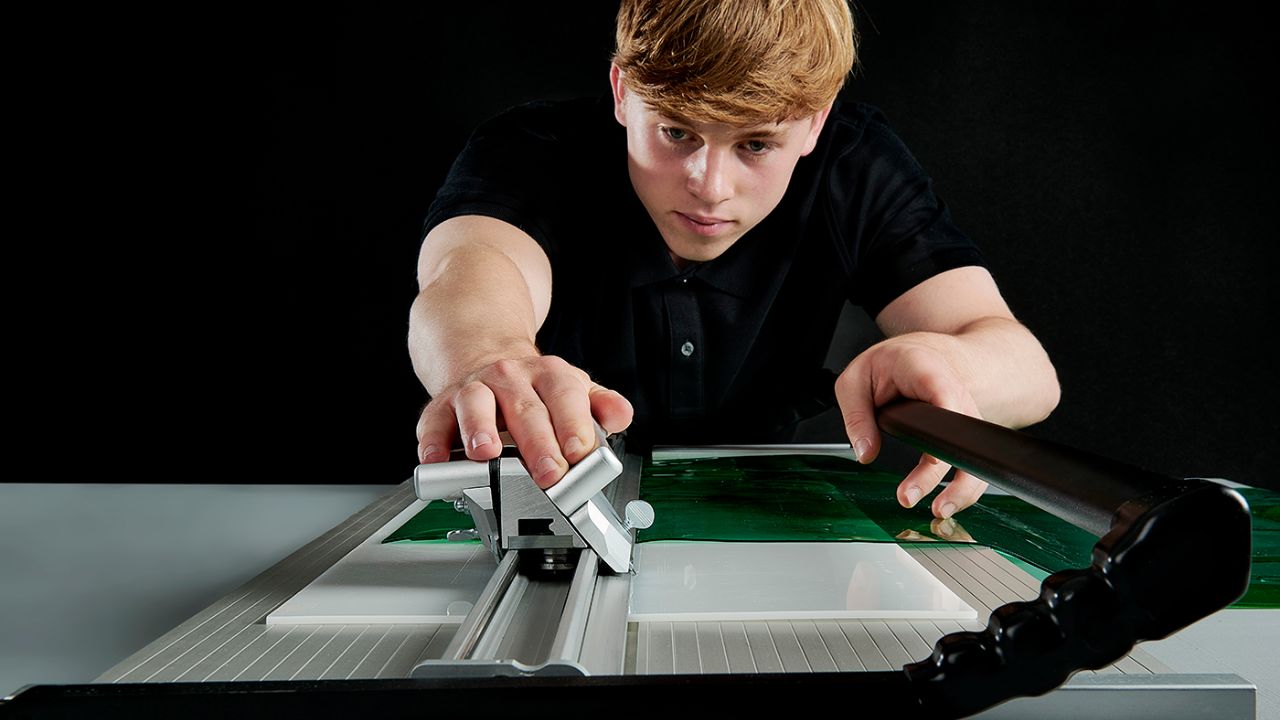

Automation

Engraving technology in terms of automation of the processes reduces the probability of human interference and improves the effectiveness of the processes. There are automated engraving machines that are fitted with sophisticated software that enables them to run for long periods without supervision as they produce engraved products of equal quality and thus decrease operating expenses. This technological change gives the freedom of printing companies to enhance production and invest their resources.

Environmental Considerations and Sustainability

Since environmental issues remain relevant in industries across the globe, the flexographic printing industry is not an exception. The development of engraving technology is directly connected with initiatives aimed at the minimization of the environmental impact of printing. For example, laser engraving has less waste than traditional technologies, as it does not require etching with chemical solutions and consumes much less material. In addition, the availability of environmentally friendly materials in the manufacture of printing plates and the recent innovation of water-based inks are other supporting sustainable practices in engraving technology. All these innovations help in making the printing process more environmentally friendly, thus helping the company adhere to the global call for environmental conservation and sustainable production.

Customization and Personalization

The importance of packaging and labeling has significantly increased in the last few years due to the need to have products that are unique and customized. This trend has been addressed by engraving technology in flexographic printing to allow for high levels of customization with accuracy. It means that brands can create limited editions of plates, promotional items, and labels that will be appealing to the target audience. Digital engraving especially enables the printer to provide for a client’s demand without necessarily having to order the engraving plate, hence enhancing the on-demand customization. In doing so, this capability increases brand identification and customer loyalty, thus providing organizations with a competitive advantage within the current saturated market environment.

Conclusion

The advancement of engraving technology in flexographic printing of the future is characterized by astonishing growth in quality, speed, and environmental friendliness. Recent advancements such as laser engraving, digital integration, and automation are changing the engraving industry by providing efficient and accurate engraving procedures and cutting down on costs and pollution. Technologies such as customization and personalization remain favorites for consumers and thus the flexographic printing industry stands to benefit from such advancements. Adopting such innovations will not only help the industry to grow but also help in realizing a better and more progressive future for the print industry.